PLI International

High Density Interconnect (Hdi) PCBS

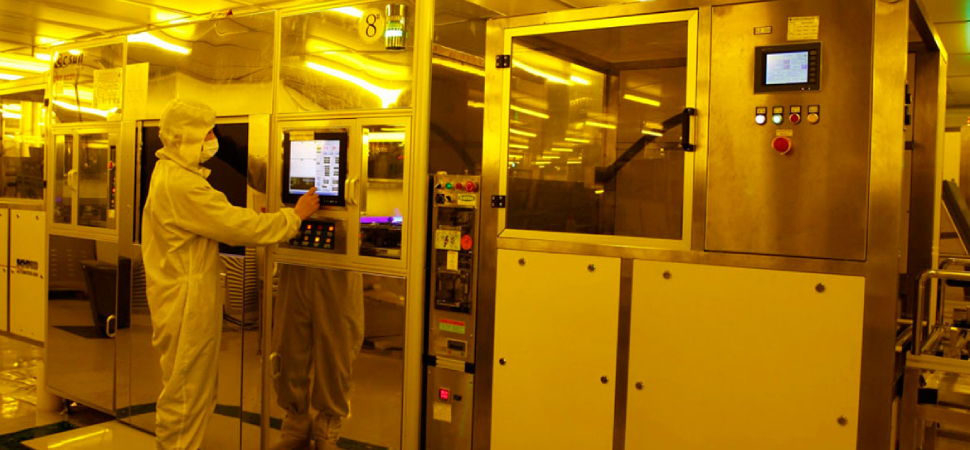

High Density Interconnect (HDI) PCBs are a type of printed circuit board (PCB) technology that allows for the creation of PCBs with a high density of components and interconnections in a small form factor. HDI PCBs are widely used in the electronics industry for applications such as smartphones, tablets, medical devices, and automotive electronics.

PLI International

High Density Interconnect (Hdi) PCBS

HDI PCBs use advanced manufacturing techniques and materials to create smaller vias and finer trace widths, enabling a higher density of components and interconnects on a PCB. Some common HDI PCB technologies include:

Microvias: These are very small vias with diameters of less than 150 microns. They can be placed in very tight spaces, enabling a higher density of components on the PCB.

Sequential Lamination: This is a process where multiple layers of PCBs are bonded together using advanced materials and techniques, creating a highly dense and compact PCB.

Laser Drilling: This is a process where a laser is used to create very small vias in the PCB, enabling a higher density of components and interconnects.

HDI PCBs offer several advantages over traditional PCBs, including:

Smaller size and higher component density: HDI PCBs can pack more components into a smaller area, enabling the creation of smaller and more compact electronic devices.

Improved signal integrity: HDI PCBs can reduce the distance between components, which can improve signal integrity and reduce noise.

Increased reliability: The use of advanced materials and manufacturing techniques in HDI PCBs can improve their reliability and reduce the risk of failures.

Overall, HDI PCBs are a critical technology in the electronics industry, enabling the creation of smaller and more advanced electronic devices.

flex boards / hdi